|

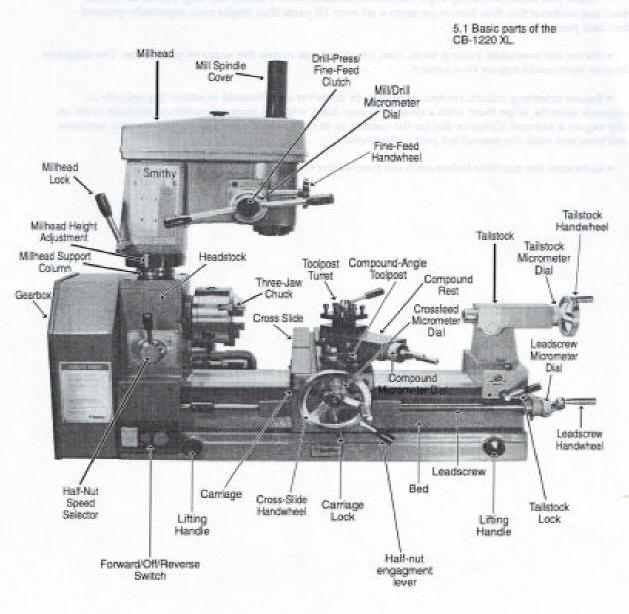

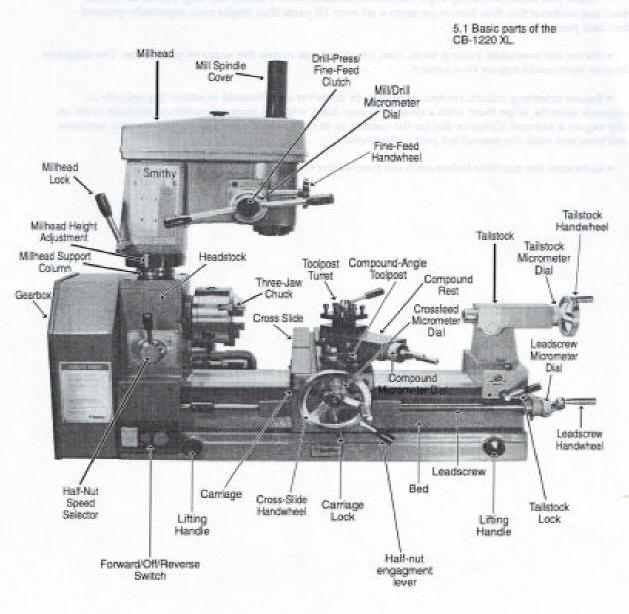

Bed

The bed is the

machine’s foundation. It is heavy, strong, and built for

absolute rigidity. The two ways on the top are the

tracks on which the carriage and tailstock travel. To

maintain an exact relationship between tool point and

work piece from one end of the machine to the other, the

ways must be absolutely true and accurately aligned to

the line of centers and to one another.

Carriage

The carriage consists

of the saddle and apron. It moves by hand or power along

the bed, carrying the cross slide, compound rest, and

tool post. Its function is to support the cutting tool

rigidly and move it along the bed for different

operations. It locks into place by tightening the

carriage lock under the cross-slide hand wheel.

Change gears

The change gears cut

different thread pitches. They also determine the feed

rate. Five change gears come installed on the machine;

others are packed with it.

Compound rest

Mounted on the cross

slide, the compound rest swivels to any angle horizontal

to the lathe axis to produce bevels and tapers. Cutting

tools fasten to a tool post on the compound rest. The

calibrations on the front of the base are numbered in

degrees from 60° right to 60° left.

Cross slide

The F-slotted cross

slide moves crosswise at 90° to the lathe axis by

manual turning of the cross-feed screw hand-wheel. It

also serves as the milling table.

Drill-press and fine-feed clutch

Pushing in the

drill-press clutch engages the fine feed. To work the

clutch, release the spring tension by rotating the

drill-press handles clockwise. Pull the clutch out to

use it as a drill press or push it in to use the fine

feed. Use the fine-feed hand wheel to move the quill up

and down.

Forward / Off / Reverse switch

This is the main switch

used to operate the lathe it is simply a forward /

reverse switch for the motor. The motor turns

counterclockwise for normal lathe operation and

clockwise for normal milling and drilling.

Gearbox

The gearbox houses the

belts that drive the spindle and change gears for the

power feed. Select the thread pitch (for threading) or

the feed rate (for turning) by changing the four change

gears on the right side of the gearbox.

Half-nut engagement lever

This lever, located on

the apron, transmits power to the carriage when rotated

9O° to the right.

Half-nut speed selector

The two-speed selector

for powering the lead screw is on the front of the

headstock. The lead screw turns twice as fast in the II

position as in the I position.

Headstock

The headstock, which is

secured to the bed, houses the gears that drive the

power feed and the taper bearings that secure the lathe

spindle.

Lathe belt tensioner

To adjust the lathe

belt, pull the tensioner handle forward to tighten the

belt, back to loosen it.

Lathe/mill/drill clutch

The lathe/null/drill

clutch is inside the gearbox. A three-position clutch,

it transfers power to either the lathe or the mill, but

not to both at the same time. To engage it, rotate it

slowly while pushing Sight or pulling on the clutch

sleeve. Pulling it to the left runs the lathe, to the

right (all the way in) runs the mill/drill. The middle

is neutral.

Lathe spindle

The end of the lathe

spindle facing the tailstock is the spindle nose. The

spindle nose, which has an MT4 taper, rotates the work

piece and drives lathe chucks and other work holding

devices. All attachments, such as three and four-jaw

chucks, bolt to the spindle flange either directly or

via an adapter plate.

Lead screw

The lead screw, which

runs the length of the bed, moves the carriage for lathe

turning or thread cutting. It works both manually and

under power. You can also use it manually with the mill.

Locks

Locks on the cross

slide, carriage, quill, and tailstock (two), keep them

from moving. During machining, lock all locks except

the one on the part you want to move.

Micrometer dial collars

Just inside the handles

of the tailstock, cross feed, drill press, compound

feed, and lead screw there are collars calibrated in

inches. The compound feed, lead screw, and cross feed

are calibrated in two-thousandths, the tailstock in

thousandths, and the drill press in 4O-thousandths.

These micrometer dial

collars can move independently around the handle shafts.

This independent motion is called float. Floating dials

on the cross slide, tailstock, and lead screw let you

zero the collars at any point and read the feed travel

from that point on the dial for added accuracy.

Mill-belt tensioner

To adjust the mill belt

, swing the roller assembly to the front and place the

belt on the back of the roller. Loosen the roller

assembly and slide it back and forth in its slot.

Millhead height adjustment

Unlock the mill-head

lock and place the height adjustment handle in one of

the three holes in the black collar. Turn the collar to

raise and lower the mill head.

Mill spindle

The mill spindle

attaches to the quill, which moves fri and out of the

head. The quill lock keeps the quill still when you

install or remove tools from it and while milling

horizontally. Usually, tools fit into collets that

attach through the spindle via drawbars.

Tailstock

The tailstock, which

provides right-end support for the work, moves along the

bed and can stop at any point. It has an MT3 taper and

holds centers, drills, reamers, taps, and other tools.

To move the tailstock spindle, turn the tailstock hand

wheel.

To offset the

tailstock, adjust the two base-locking bolts. To offset

to the left, loosen the left adjusting bolt arid tighten

the right. To offset to the right, loosen the right

adjusting bolt and tighten the left.

|