|

Instructions:

Initialization procedures

Plug in the pump motor.

Turn on air pressure and set to 60 psi.

Do a visual inspection of the cutting blade

for defects.defects.

Note position of the emergency stop button. button.

Prepare sample to extract specimen

Extract a specimen of about a ¼ inch in

height.

The sample should be of small size.

Put sample into vise, making sure to lock

both sides.

Close cover.

Cutting specimen

Press ‘Auto Start’.

When cutting process is completed, press ‘Stop

Reset’.

Open cover and remove sample and the

specimen.

Clean-up and shut-down

Turn on pump and use water hose to clean

particles.

Set air pressure to zero.

Unplug power.

Leave hood open to dry.

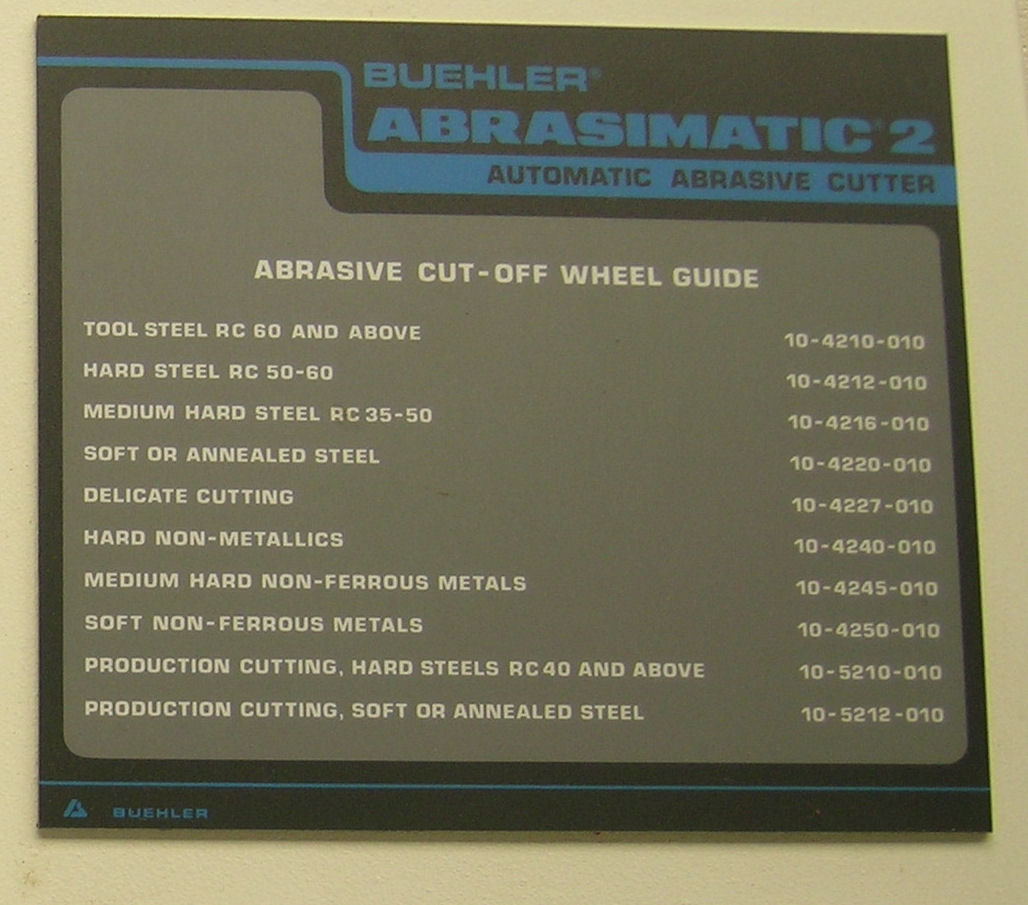

Listed below types of blades:

|